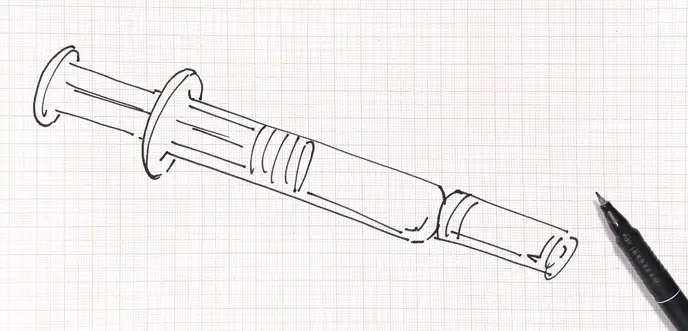

Drug containment and delivery services Realizing new containment solutions for your drug product requirements

CONTACT USDeveloping customized drug containment and delivery solutions

Sometimes, established containment solutions don’t match the specific needs of a new drug product or an intended lifecycle adaption. With SCHOTT Pharma’s drug containment and delivery services, the right drug container is customized for your product’s specific needs – from system design, through prototyping, to process implementation and GMP-compliant documentation.

The scope of drug containment and delivery development includes:

-

Primary packaging containers (e.g. syringes, cartridges, vials, or ampoules)

-

Containment system components (e.g. plungers, closures, closure systems, and integrated needles)

-

Adjacent components (e.g. plunger rods and backstops)

-

Outer packaging for infeed of primary packaging to the filling line and transportation

-

System development as a combination product

-

Device-containment alignment

Feasibility studies

SCHOTT Pharma helps you to evaluate the feasibility of new or customized containment solutions. We translate your requirements into a product concept, review its feasibility, and deliver a proposal for realization.

Prototyping

From the beginning of a new containment solution project, SCHOTT Pharma can manufacture prototypes and samples for early-stage or machinability testing.

Design and development

SCHOTT Pharma will turn a design concept into a reliable drug containment product, with implementation involving component sourcing, defining the production process, and verification testing.

Design History File (DHF) documentation

SCHOTT Pharma records and summarizes the design history throughout the development process, so that the product development path is comprehensible from design concept through to finished product.

A dedicated project manager guides your solution through development

Once the requirements of your containment and delivery solution have been jointly defined, a SCHOTT Pharma Project Manager will follow a stage-gate process to take your solution from concept to industrialization.

In this established process, design reviews combined with internal and joint steering committees or review teams will ensure information is exchanged, requirements are met, and steady progress is made towards joint objectives.