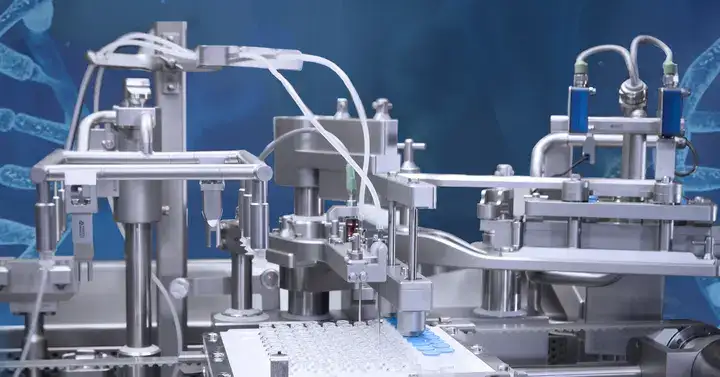

Fill-and-finish services Support for the processing of containment solutions from small to commercial scale

CONTACT USEnabling early-stage sample filling and efficient commercial fill-and-finish

For customers without the capability for sample filling, SCHOTT Pharma can fill syringes, cartridges and vials for early-stage testing. Sample preparation and storage capabilities allow engineers to test and examine the interdependencies between fill-and-finish processes and accelerated aging of drug-container interaction under controlled laboratory conditions.

One key aspect for the long-term success of SCHOTT Pharma customers is the compatibility of our containment solutions with efficient commercial processing, which is why we consider process compatibility a key priority in solution design. SCHOTT Pharma offers a number of services to assure compatibility and optimize line efficiency, including:

- Compatibility assessment for a systematic review of compatibility between secondary packaging, containment solution, and line equipment.

- Toolbox and consultancy for a systematic review of the origins of glass breakage and cosmetic defects, plus line maintenance.

Filling line compatibility verification

SCHOTT Pharma provides proactive exchanges and assessments with leading manufacturers to ensure general compatibility. We also offer compatibility assessments and testing for your specific line.

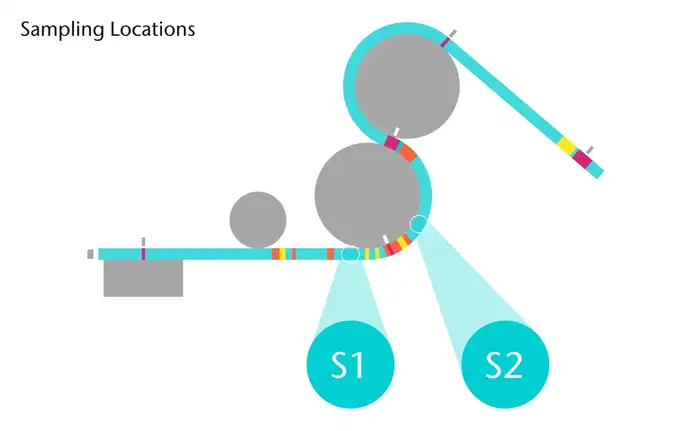

Filling line efficiency optimization - identifying potentially critical spots

The application of Smart Skin sensor drones enables the detection of critical spots of high mechanical pressure or vibration along your line, as well as reveals changes of the line state.

Filling line efficiency optimization - assessing critical impact

SCHOTT Pharma provides glass analytics for the assessment of line modules with respect to container strength reduction and the origins of damage or breakage.

OEE optimization consultancy for fill-and-finish

Achieve maximum reliability for your line output by working with SCHOTT Pharma’s experts, combining the strength of sensor drone measurements from Smart Skin Technologies with our unique expertise in glass analytics.

Joint line assessment and sensor drone investigations enable easy identification of potentially critical locations for container damage specific to your line. Based on glass analytics, SCHOTT Pharma’s team helps to identify critical issues, collect additional insights on root causes, and assess potential optimization measures.

Benefit from our fill-and-finish expertise

Using our long-term experience of containment solutions, we understand that many problems do not occur at just one customer site. With each additional case, we have gained insight, improved best practices, and built a growing network of industry experts.

At SCHOTT Pharma, we are happy to share our knowledge to make your project a success. Contact us to find out more about our fill-and-finish services.