SCHOTT Pharma - Drug containment solutions and delivery systems for injectable drugs

For more than 100 years, the SCHOTT name has represented advanced solutions and services for the global pharmaceutical and biotech industries. With this longstanding expertise, SCHOTT Pharma provides an extensive and scientifically proven product portfolio for the safe storage and administration of injectable drugs to patients all over the world.

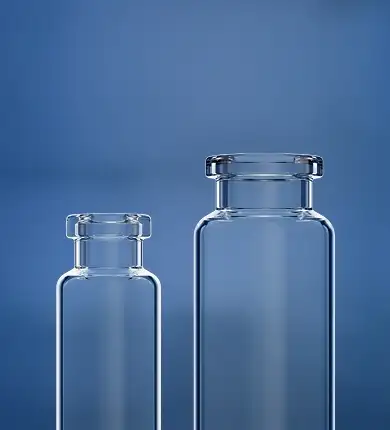

SCHOTT Pharma`s portfolio ranges from prefillable syringes, cartridges, vials, and ampoules to analytical, development, fill-and-finish, and regulatory services for pharmaceutical companies, biotechs, and CDMOs.

Setting industry standards, we provide drug containment and drug delivery solutions from single components to complete holistic systems to ensure compatibility across the entire pharma value chain, ranging from clinical trials and drug administration to the regulatory and commercial filing.

As scientists and engineers, everyone at SCHOTT Pharma strives for uncompromising quality in our products and services, which adhere not only to industry standards, but set the pace for continuous innovations. We rely on science in everything we do, because human health matters.

Spanning the entire value chain, from the raw material to the patient

Solutions grounded in science to ensure medicines are safe and easy to use

The accelerated growth in biological and highly potent pharmaceutical formulations poses challenges for drug filling and handling. In terms of pharmaceutical drug development, this primarily involves analytical and technological challenges, but also challenges related to drug storage.

Requirements of primary drug containers such as vials, syringes, cartridges, and ampoules have become more complex due to factors such as advances in mRNA applications. SCHOTT Pharma offers one of the largest product portfolios in the market to meet the needs of even the most complex drug formulation.

Syringes - Safe, simple, and reliable drug storage and injection

Cartridges - Exceptionally accurate dosing

Vials - Secure storage of liquid drug formulations

Ampoules - Safe and stable storage from production to administration

Upcoming Events

Learn more about drug containment and delivery solutions in-person or online